Bai Shui Chao

Email: dl-bsc@dlsjmj.com

Telephones: 13962423309

Mark Yen

Email: dl-mark@dlsjmj.com

Telephones: 17312472090

TEL:0512-57170368

FAX:0512-57170328

HTTP://www.bjczg.com

Add: No.218 South Yucheng Road Kunshan City Jiangsu Province China.

Adele is a professional air compressor equipment manufacturer, headquartered in Belgium. Since its establishment, plastic products have never been used. This time, we specially visited Kunshan Daliang. We hope that our company can analyze their equipment and analyze the feasibility of replacing steel with plastic parts for some parts.

I. workshop visit

The overall 6S of our mould workshop is very praised. In the impression of our guests, the mould workshop is synonymous with cold, dark, oppressive and greasy. Many times, we are reluctant to visit the mould workshop of the factory. Kunshan Daliang plastic mould Co., Ltd. is a medium-sized enterprise with 15 years of mould development experience. We have been undertaking export commercial moulds for many years. Many foreign customers feel that our mould workshop gives them a sense of comfort, and they are more willing to stay in the workshop to directly explore the mould and product problems with technical personnel.

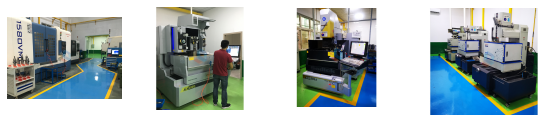

II. Equipment evalsuation

Since 15 years of mold development experience, Kunshan Daliang has been aware of the pain of customers for mold suppliers. For mold factories with incomplete mold processing equipment, many customers are unable to discuss and solve problems on the spot, because there is no way to get a clear plan and verification time soon, they prefer to stay in the company's office and be handled by the suppliers themselves, resulting in the result that It's the whole project cycle that is forced to drag on for a long time.

For European customers and Japanese customers, the requirements for die closing accuracy of large molds are still very strict. The traditional hammering does not meet their technological requirements. They came to inspect the factory and agreed with us that we should use the die closing machine to carry out parting line die matching for large molds.

III. discussion of problems

The customer's current problem is: the water pipe bracket inside the cooling body needs to be temperature resistant 30-90 degrees, the pH value of the aqueous solution changes from 6.5 to 9, the bracket can guarantee the service life of 3 years, but also can play a sealing role in nearly 90 holes and the outer circle edge. Can the plastic meet the previous parts carved and milled by brass (with sealing ring)?

Answer: through the customer's description of the role and use environment of the parts, we give the analysis results as follows:

1. The material itself shall be resistant to hydrolysis, acid and alkali;

2. The material itself has toughness, and seals around the assembly circle through its own structure

Considering the environmental requirements, the plastic can completely replace the original copper parts, greatly saving assembly time, improving efficiency and reducing cost.

Four, farewell

Finally, we integrated the cost and problems of the guests, and gave 4 schemes for the guests to choose. The discussion results were gratifying. Finally, the guests left with the definite scheme results, and the recognition of Kunshan Daliang's 15 years of mold development experience came naturally.